Hover your cursor

Hover your cursor

Model Name

SBP-091-01-1

Basic Specifications

· Check the alarm and message for each process.

· Setting the working conditions according to the product.

· Manual operation function by process.

· Currently, daily set quantity and total production quantity counters.

· HEATER open circuit alarm

· Storage hopper (25L dual hopper).

· Storage Hopper Insulation Dry Heat HEATER. (750 W)

· Rounder cutting 5R.

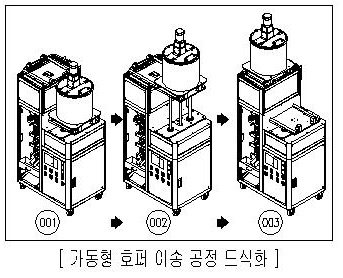

Work process

Primary Upper: Vertical Adhesion → Secondary Lower: Horizontal Adhesion and Cooling → Third Fall Transfer → Fourth Cutting

production capacity

16-18 packs/min (based on 5g)

<Features>

It has a compact design and slim shape, so it is good to install in small places.

<Production specifications by process>

A. FILLING DEVICE

* SCREW ROTATION QUANTIFICATION FILLING SYSTEM

* Medium capacity: 5g to 30g.

* Filling volume control: Invert screw rotation control.

* Materials used: AL6061, SUS304

B. SEALING DEVICE

* HEATING HEATING TYPE HEATING COMPRESSION SYSTEM.

Upper HEATER: %15 × 175 cm = 1 piece

Electricity: 220 V (400 W)

* HEATING HEATING TYPE HEATING COMPRESSION SYSTEM.

Lower HEATER: %15 × 50 cm = 2 pieces

Electricity: 220V (120W)

* Temperature control: Digital control.

* SEALING HITA MATERIAL BS (HEATER BODY).

C. Cutting and SEALING

* Cutting: 5R

SEALING: Width: 25–40 mm (optional), Length: 100–150 mm (adjustable).

D. Driving method

* pneumatic pressure

<CONTROL SYSTEM>

* Control Method: PLC + Touch Screen.

<Structure>

* FRAME: SUS304 (T5) and AL60 profiles.

Workpiece: SUS, and AL6061.

<Equipment Specification>

a. Full voltage: 220V / 60hz

b. Power consumption: 3.0Kw (Max)

c. Air pressure: 5–6 kg/cm₂

d. Equipment weight: 150 kg.

e. Equipment specification: 830 cm (L) × 830 cm (W) × 2250 cm (H)

<Main components (KS products)>

1. PLC - LS.

2. Touchscreen - LS.

3. AIR Cylinder - TPC.